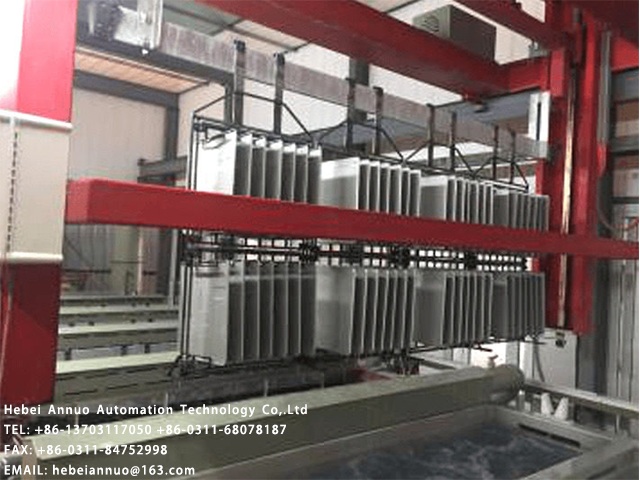

Before the formal processing and pickling, the galvanized steel pipe needs to do some acid treatment work, so as to ensure that the materials used are all qualified and effectively extend the service life of the steel pipe, then the Pretreatment (small parts) automatic roller pickling line has What process links? Let's take a look at it below.

The first stage - pretreatment

All steel sheets and steels must be surface treated before they are processed into products to produce high quality products that give them the best performance. The surface treatment is divided into two stages. The first stage is the pretreatment of the surface of the material to remove the rust and stains on the surface of the steel, and the scale, and then remove the protective primer. It has been proved that many unqualified steel plate substrates are caused by improper surface treatment, so it is necessary to pay attention to the pretreatment (small parts) automatic roller pickling line during production.

The second stage - secondary derusting

Before the material is processed into pieces, professional coating pretreatment is required, which is what we often call “secondary descaling”, but the secondary descaling treatment is not very long in the pretreatment automatic roller pickling line. Generally, depending on the actual situation, whether to adopt secondary descaling is selected.

In short, the role of the Pretreatment (small parts) automatic roller pickling line in the galvanizing process is still very important, especially if the pretreatment is not done properly, it is very influential to the galvanizing effect, and the pre-treatment small parts can be effectively selected. Improve the performance of galvanized products. So, in general, choosing the right Pretreatment (small parts) automatic roller pickling line helps to improve the quality of the process and give the substrate the best performance.

TEL: +86-13703117050 +86-0311-68078187

FAX: +86-0311-84752998

WhatsApp: 0086 137 0311 7050

WeChat: 13703117050

EMAIL: hebeiannuo@163.com

ADDRESS: Shijiazhuang City,Hebei Province, 051530,China